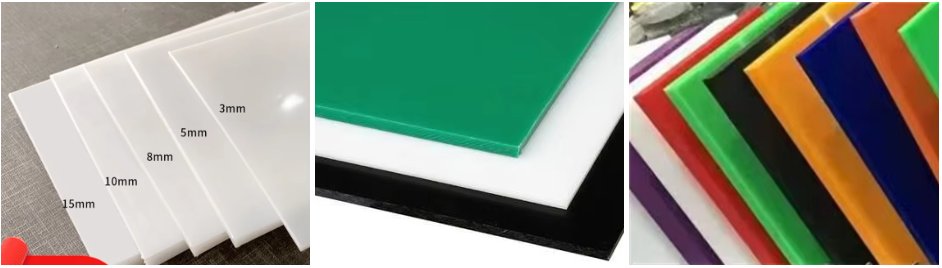

The PP PE Board Plastic Board Making Machine is a robust solution tailored for producing thermoplastic panels used in packaging, logistics, and storage.

PP thick plate can be widely used in the chemical industry, food industry, anti-corrosion industry, purification industry, environmetal protection equipment production industry.

PE plate can be widely used in chemical industry, electric power and other industries. HDPE plate can also be used as engineering plastics in machinery, chemical and other equipment, widely used in the manufacture of ice hockey field wall panel.

We also can make PVC, ABS, PC thick board which can be used in widely industries.

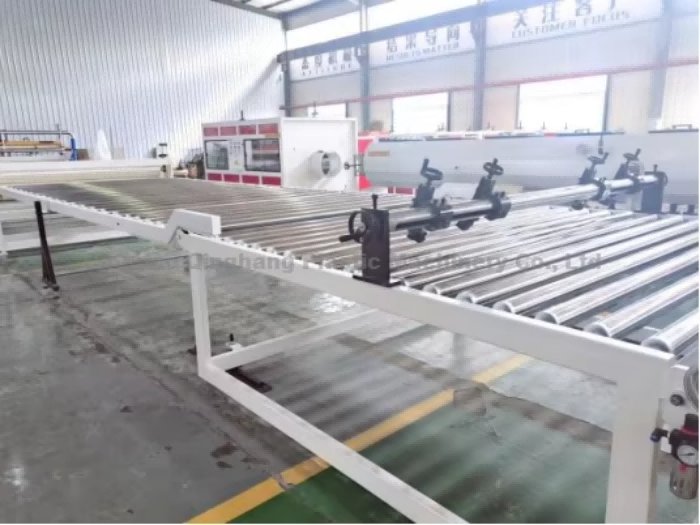

THE WHOLE PP PE BOARD PLASTIC EXTRUSION MACHINERY LINE

Vertical mixing + spiral feeding machine

1) Vertical mixing machine

Capacity: 500kg

Material: 201 stainless steel

Power: 4kw

Mixing method: internal spiral lift

2) Spiral feeding machine

Feeding method:limit control automatic feeding

Power:2.2kw

Material: 201 stainless steel

SINGLE/DOUBLE-SCREW EXTRUDER

The high-efficiency single screw extruder adopts a two-stage overall design, strengthening the plasticizing function, ensuring high-speed, high-performance, and stable extrusion. The special barrier comprehensive mixing design ensures the mixing effect of the material, and the high shear and low melting plasticizing temperature ensures the high-performance, low-temperature, and low-pressure metering extrusion of the material.

We also have double screw extruder for material PVC, PC and etc.

HYDRAULIC SCREEN CHANGER

Hydraulic station motor power:3kw

Heat power: 6kw

Structural style: double station, single plate type, automatic hydraulic screen

Changer drive: hydraulic system, manual control

Material: alloy steel 40Cr, baffle and sealing ring 38CrMoAl

HANGER-TYPE SHEET CO-EXTRUSION DIE

The clothes rack type co extrusion extrusion mold can improve product quality, reduce natural irregular flow, and enable various plastic polymers to be extruded and continuously stable.

THREE ROLLER CALENDER

The working principle of three-roller calender is to put the material into the middle roller of the calender, and then the upper and lower rollers press the material into the required shape according to certain pressure and speed. The pressure between the upper and lower rollers can be controlled by changing the distance between the two rollers. Generally, the upper roller rotates and the lower roller is stationary, and the middle roller rotates at the same time to ensure the uniformity of the rolled material.

ROLLER TEMPERATURE CONTROL SYSTEM

Cooling medium: conduction oil

Precision of temperature control: ±1℃

Heat power: 15KW*3

Oil pump power: 3X3.7KW

Water inlet valve: pneumatic angle seat valve

FIRST TRACTION MACHINE

Pull roll diameter: φ250mm

Length: 1800mm

Power: 1.1kw

Powtran nitrile rubber roller cylinder compression

The plate is naturally cooled

ROLLER COOLING BRACKET

The plate is naturally cooled and formed

Roller bracket length: 24m

Roller diameter: Ø76mm

Wall thickness:2mm

Roller material: stainless steel

Roller length: 1800mm

LONGITUDINAL TRIMMING DEVICE

Cutting method: high speed steel cutter, two cutters are divided into 2 groups can adjust the cutting width at will manual adjust the blade position

Qty of blade: 2pcs

SECOND TRACTION MACHINE

Pull roll diameter: φ250mm

Length: 1800mm

Power: 1.5kw

Powtran traction speed: 0.2-1.5m/min

Nitrile rubber roller

Cylinder compression

The traction speed can be adjusted separately or in accordance with the speed of the three-roller calender

ACROSS CUTTING MACHINE

This machine has a high degree of automation, simple operation, low noise, and a good safety device. The automatic lifting of the feeding roller device is designed with a humanized design, making it faster and more efficient in the cutting process, making it durable and wear-resistant.

AUTOMATIC UNLOADING RACK

Roller diameter: Φ75mm

Effective width: 1500mm customized as customer's request

Stainless steel table

Equipment list

MAIN EQUIPMENT | ||

NO. | Description | Qty |

1 | Vertical mixing + spiral feeding machine | 1 set |

2 | Exhaust single screw extruder | 1 set |

3 | Hydraulic screen changer | 1 set |

4 | Hanger-type sheet co-extrusion die | 1 set |

5 | Vertical type three roller calender | 1 set |

6 | Roller temperature control system | 1 set |

7 | First traction machine | 1 set |

8 | Roller cooling bracket | 1 set |

9 | Longitudinal trimming device | 1 set |

10 | Second traction machine | 1 set |

11 | Across cutting machine | 1 set |

12 | Unloading bracket rack | 1 set |

13 | Electrical control system | 1 set |

ACCESSORY EQUIPMENT(optional) | ||

14 | Resin high speed mixer and cooling mixer | 1 set |

15 | Water cooling chilling machine | 1 set |

16 | Crusher | 1 set |

17 | Milling machine | 1 set |

18 | laminating machine | 1 set |

model | board width(mm) | board thickness(mm) | power(kw) | output(kg/h) | screw diameter(mm) |

SJ120/36 | 1200 | 20 | 132 | 400 | 120 |

SJ120/36 | 1500 | 10 | 132 | 400 | 120 |

SJ150/36 | 2000 | 10 | 250 | 800 | 150 |

If you have any questions or needs about the product, please fill in the following form and we wll contact you as soon as possible.

Get to know about Hunfund Ronpak, our updates and all news, straight to your inbox.

No.7 Tongxin Road, Nanguan Industrial Park, Jiaozhou City, Qingdao

Sale1@qhplasticmachinery.com bryan@qhplasticmachinery.com Petya@qhplasticmachinery.com

+86 13791964969 +86 18765250198 +86 13070823358

Whatsapp: +8619525325080 +8618765250198 +8613070823358