Model: QH-PP/PE Series

Sheet Width: 500mm – 3000mm

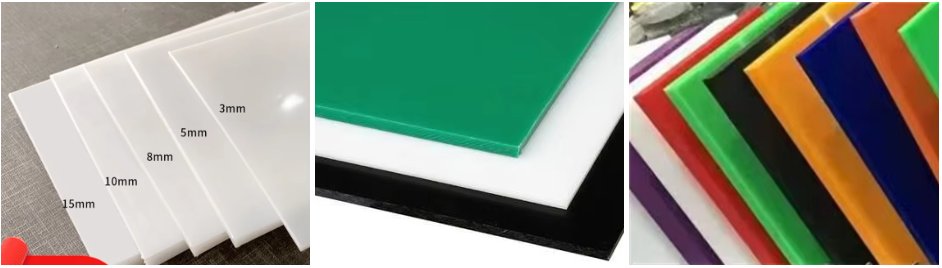

Sheet Thickness: 1mm – 40mm

Materials: PP / PE / HDPE / LDPE

Output Capacity: 200 – 1000 kg/h

Extruder Type: Single Screw Extruder

Control System: Siemens PLC + HMI Touch Panel

Roller System: Three-Roller Calender (Vertical or Oblique)

Applications: Thermoforming, Stationery, Food Packaging, Construction

Reliable, customizable, and energy-saving — your smart choice for plastic plate production.

Contact us for custom machine configuration and pricing!

1.Product Overview

Our PP/PE Sheet Extrusion Line is engineered for the continuous production of flat, smooth, and uniform

sheets from polypropylene and polyethylene. The line is suitable for various downstream applications

including thermoforming, packaging trays, stationery sheets, and construction boards.

With a modular design and high level of automation, this line provides excellent efficiency, product quality,

and operational reliability.

2.Key Features

• High Output & Stable Operation: Equipped with a high-efficiency single screw extruder and precision gear pump.

• Versatile Material Processing: Compatible with both virgin and recycled PP/PE/HDPE/LDPE materials.

• Accurate Thickness Control: T-die + three-roll calender system ensures sheet uniformity.

• Flexible Sheet Configuration: Mono-layer or multi-layer structures available on request.

• Smart Control System: Siemens PLC with HMI touch screen for centralized control and fault alarm.

• Optional Equipment: Embossing roller, edge trimming, static eliminator, stacker or winder.

3.Typical Applications

• Disposable food packaging trays

• Stationery products (folders, binding covers)

• Medical trays and blister packs

• Waterproofing & protective construction boards

• Industrial packaging sheets

4.Why Choose QH Machinery?

• Over 15 years of experience in plastic extrusion machinery

• CE & ISO certified production process

• Fully customized solutions according to your product size and capacity

• On-site installation, training, and lifetime technical support

• Exported to more than 50 countries with stable performance

Equipment list

MAIN EQUIPMENT | ||

NO. | Description | Qty |

1 | Vertical mixing + spiral feeding machine | 1 set |

2 | Exhaust single screw extruder | 1 set |

3 | Hydraulic screen changer | 1 set |

4 | Hanger-type sheet co-extrusion die | 1 set |

5 | Vertical type three roller calender | 1 set |

6 | Roller temperature control system | 1 set |

7 | First traction machine | 1 set |

8 | Roller cooling bracket | 1 set |

9 | Longitudinal trimming device | 1 set |

10 | Second traction machine | 1 set |

11 | Across cutting machine | 1 set |

12 | Unloading bracket rack | 1 set |

13 | Electrical control system | 1 set |

ACCESSORY EQUIPMENT(optional) | ||

14 | Resin high speed mixer and cooling mixer | 1 set |

15 | Water cooling chilling machine | 1 set |

16 | Crusher | 1 set |

17 | Milling machine | 1 set |

18 | laminating machine | 1 set |

model | board width(mm) | board thickness(mm) | power(kw) | output(kg/h) | screw diameter(mm) |

SJ120/38 | 1500-2000 | 3-10 | 132 | 400 | 120 |

SJ150/38 | 1800-2400 | 3-10 | 220 | 550 | 120 |

SJ180/36 | 2600-3000 | 15-40 | 315 | 1000 | 150 |

If you have any questions or needs about the product, please fill in the following form and we wll contact you as soon as possible.

Get to know about Hunfund Ronpak, our updates and all news, straight to your inbox.

No.7 Tongxin Road, Nanguan Industrial Park, Jiaozhou City, Qingdao

Sale1@qhplasticmachinery.com bryan@qhplasticmachinery.com Petya@qhplasticmachinery.com

+86 13791964969 +86 18765250198 +86 13070823358

Whatsapp: +8619525325080 +8618765250198 +8613070823358